Funding application for 2024 – 2025 are now open Apply Now

Member Portal

Not a member? Join us here

Foodstuffs is trialing alternatives to single-use plastic produce bags during the month of July as it moves to lead in the upcoming plastics phase-out.

6 July 2021

The trial is part of the company’s commitment to Pledge 2025 – to make all its packaging recyclable, reusable or compostable by 2025 – and comes after Government announced a phase-out of difficult-to-recycle plastics and some single-use plastic items between 2022 and 2025.

New World, PAK ‘n SAVE and Four Square customers can expect to see a range of reusable alternatives on offer such as multi-use bags, nylon bags, mesh bags, organic cotton bags, and collapsible crates.

The Packaging Forum is working with other key stakeholders (including composters) on resolving the issues surrounding compostable packaging. This consultation is a critical part of our collaborative work programme to progress solutions for this packaging type.

Published 3 June 2021

Consultation closes 30 June 2021

Compostable packaging has significant value in the packaging system in specific applications where it can bring nutrients to composters for composting, thus diverting organic waste from landfill. Globally, diverting wasted food from landfill is a priority. In New Zealand (NZ), our Climate Change Commission recently declared organic recycling a top priority for reducing carbon emissions in the waste industry, alongside capturing more methane from landfills.

“Compostable packaging” incorporates a wide range of material types used in a variety of applications. However, some applications are not globally considered as best practice for the generally accepted “use case” for compostable packaging.

In this consultation document we aim to discuss:

Consultation closing date: 30 June

Download the consultation document

How to make a submission

Simple submissions with answers less than 50 words per question may be submitted through our online survey.

For more detailed submissions, please email your submission, preferably in a word document.

Emailed submissions will need to include the following information:

Email your detailed submission

Next steps

Following the closing of the consultation, we will be analysing the results and publishing a summary document which will include recommendations.

Frucor Suntory has introduced cardboard packaging for its multipacks of Pepsi, Pepsi Max, Mountain Dew and 7UP.

04 May 2021

The change is one of several the Australasian beverage company has undertaken to help achieve its sustainability goal of zero waste to landfill by 2030.

The cardboard replaces shrink wrap and will remove 2.7 million pieces of plastic from going to landfill each year as well as making it easier for customers to recycle the packaging.

Read more here.

DB Breweries has set a list of ambitious sustainability targets alongside the launch of its 2020 Sustainability Report.

03 May 2021

The company has announced it aims to use only energy from renewable sources, reach zero waste to landfill in production, and balance all of the consumed volume of water it uses, by 2030.

Read more at dbsustainability.co.nz

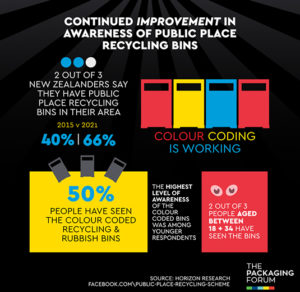

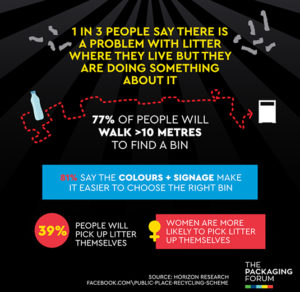

A recent survey on public place recycling and litter has seen a mixed bag of results, with awareness around public bins increasing but willingness to make extra effort to use them declining.

07 April 2021

The survey, conducted in early March by Horizon Research for The Packaging Forum, also found more people believe there is a problem with litter where they lived, compared with a year earlier.

The survey spoke to over 1,200 people about public place recycling and rubbish bins and found the number of people who have access to public bins continued upwards to 2.4 million adults (66% of respondents). This was an increase of 2% on 2020 and 25% from the first survey in 2014.

Bins to make recycling easier, better

The Packaging Forum CEO Rob Langford says they have been working over recent years to rollout new colour-coded bins which help making recycling and disposing of rubbish easier to get right.

“There are a lot of people who want to do the right thing and recycle, but don’t have the information to do so correctly which causes unintended contamination issues. With the right information they have the potential to have a hugely positive impact.”

While awareness of these colour-coded bins declined slightly to 50%, it was still well up from 37% in 2019.

“The Covid-19 pandemic has had an impact and the research shows a drop in awareness where the bins were removed during lockdown but have not been returned,” Rob says.

It was very encouraging to see awareness was highest among people aged 18 to 24, he says. “Those aged 75 and over had just as much awareness, so it’s the group in the middle where more focus is needed.”

The colour-coded bins have continued to be very effective, Rob says, with 81% of people reporting they made knowing what to recycle and what to put in the rubbish easier. “This has been the consistent response over the past three years, so the design is working.”

More litter, less effort

He says it was interesting to see that while litter was perceived as more of a problem, with 34% people agreeing it was (up 5%), individuals were less likely to make an extra effort to use public bins. The report showed 28% of people would walk more than 40 metres to find a bin, down from 37% in 2020.

However, while attitudes towards telling someone else to pick up litter they had dropped changed little from 2020, people were slightly more likely to pick up litter themselves – up 3% to 39%.

Aspect Productivity Technology is helping its clients achieve greater sustainability through smart technology, which provides better quality information for informed decision making.

24 November 2020

Sustainability is about meeting the needs of today, without adversely impacting on the needs of tomorrow. Sustainability in manufacturing is achieved with new or improved technologies alongside sustainable business philosophies and models.

Achieving greater sustainability is also not just about production efficiencies, minimising waste and maximising resources. A well-run digital manufacturing floor helps manufacturers become more sustainable by enabling faster access to better quality information for informed decision making.

Aspect Productivity Technology, a member of The Packaging Forum, explains how their Manufacturing Execution System (MES) is doing just that, and helping its packaging customers become more sustainable.

Bonson Packaging’s sustainability philosophy

Sustainability is an important goal at Bonson Packaging in Auckland. They support a circular economy with an offering of recyclable, bio-degradable and compostable products.

The company promotes a reduce, reuse, recycle and recover philosophy and applies these practices to its operations.

An example of this is Bonson using data from the AspectPL MES software to monitor the power usage of their machines. Machine output might be the same, but power usage can fluctuate. Data from AspectPL helps Bonson reduce electricity costs and its carbon footprint.

According to Bonson, the data supplied by AspectPL has helped reduce machine power use by 5% – giving their products a smaller carbon footprint.

Proficiency allows time for efficiency, reducing downtime and waste

Cormack Packaging has saved so many man hours since it implemented an MES, it now has time to concentrate on optimising production.

“Previously our planning information wasn’t totally accurate. We’d count boxes off the machine. The machine makes the product, we pack boxes, we count the number of boxes made.

“With AspectPL we have full visibility and real-time reporting on what’s actually happening. You can easily move jobs from machine to machine and look at ‘what if’ scenarios. The AspectPL scheduler has also saved us two days per month planning 250 work orders,” says Production Manager Shaun Wallace.

“Now I can work with the guys on the factory floor to optimize production. Currently we are working on making our changeovers faster, improving our line start and line clearance downtimes, and reducing waste. With AspectPL we can see these stats at the push of a button – and in real time.’’

Monitoring and measuring manufacturing processes not only reduces waste and improves productivity. It also helps businesses pursue sustainability through better quality information that supports long-term business viability.

Aspect Productivity Technology Ltd

Aspect Productivity Technology Ltd is an Auckland-based SaaS software company. Its product AspectPL is an MES (Manufacturing Execution System) specifically designed for plastics and packaging manufacturers.

AspectPL customers gain the practical benefits of having digital data available on their manufacturing floor. They also use the data analysis and insights to achieve their sustainability philosophies.

New Zealand-owned and run food box company and Soft Plastic Recycling Scheme member Woop has rolled out their ‘Back to Base’ product stewardship programme across all of their delivery areas.

19 October 2020

The scheme sees customers return their clean and dry packaging so it can be sorted and recycled.

Woop Founder Thomas Dietz says customers have been very enthusiastic about the initiative, as demonstrated by the high level of participation in the programme. “Customers appreciate the certainty the programme provides in knowing that the packaging is being properly recycled in New Zealand.”

We chatted to him to find out more about the company and its sustainability work.

Tell us a bit about Woop – how it started and what you hope to achieve.

Since Woop started five years ago we have placed a huge focus on our commitment to the environment and we’re excited by what we can continue to do to improve.

We brainstorm and create globally inspired recipes and select and prepare ingredients using the finest local produce, ahead of time, so our customers receive beautiful ingredients and hand-crafted sauces right to their door.

The company clearly has a strong focus on sustainable practices, tell us a bit more about that.

One hundred percent of our packaging is now recyclable or compostable, and we take responsibility for that through our Back to Base programme. But our commitment to sustainability goes further than that. We see our locally sourced ingredients, portion control to avoid food waste, and delivery emissions offsetting as essential parts of our sustainability focus too.

What is the drive behind this?

As a team we are committed to reducing our impact on the environment and as a values-led business we are very passionate about it. We want to make sure that we are doing more than just our part and take responsibility to continually improve.

Was sustainability always part of the Woop business plan, or did it develop over time?

We’ve always had sustainability as a core focus of our values, however how we have engaged and implemented changes and improvements has definitely developed over time as we have learnt more.

What have been/remain the most challenging packaging items to make sustainable?

The sachets were the most challenging, as they aren’t able to be recycled through kerbside recycling. However, by partnering with Future Post we are now able to recycle them.

We have now been able to find an end-of-life recycling solution for all of our packaging. This took a lot of research.

Would you say your focus on sustainability is a point of difference or something which is becoming something of standard practice?

We see our concrete sustainability actions and our unique Back to Base product stewardship programme as a point of difference.

How do you engage with your customers to encourage them to deal with your packaging responsibly?

We are fortunate to have a direct relationship with our customers and are able to engage with them directly via phone and email.

This allows us to communicate the importance of collaborating with them on how to properly recycle the packaging they receive. This direct relationship also allows our customers to easily provide feedback and suggestions.

How have you approached sustainability with your suppliers and what are the biggest challenges there?

We require our suppliers to share their plans on improving their own sustainability and support them to make the changes we require to be more sustainable. For example, reducing packaging used in the supply chain and reducing food wastage.

What do you see as the biggest challenges for packaging sustainability overall?

Education is a big challenge. It’s really important for the public to understand the full picture when it comes to the environmental impacts of using, and not using packaging, for food.

At the moment it can be confusing for customers as to what to do with used packaging and how to make sure it’s properly recycled. There is also a lack of understanding on the functional benefits packaging brings in reducing food waste.

Do you think ‘groceries as a service’ – where many locally-based companies supply locally-sourced, regional, ready to cook produce to customers – will ever come to rival or even overtake traditional supermarkets?

These types of services are becoming more and more popular and we believe this new way of eating will continue to grow as people get busier and look to outsource parts of their lives.

What do you think the future holds for Woop in terms of business growth and the sustainability challenges that brings?

We are excited by the challenges ahead with running our Back to Base programme and being able to continue to run this initiative as the number of weekly deliveries grows. We are also continually looking for other areas we can improve and act on.

What motivated you to join The Packaging Forum?

We were motivated to join the Forum for the support network it provides and the connections it has in the recycling industry.

Para Kore and WasteMINZ have consulted with speakers of te reo Māori from local iwi, community groups, councils, universities and government departments to arrive at some agreed-on translations and some alternatives. As regional variations are still possible, WasteMINZ suggests consulting locally where possible for those intending to create signage or material. For the full resource kit, including recycling symbols, visit the WasteMINZ website.

Below are a few te reo Māori kupu that relate to recycling and packaging. For the full list, including other types of waste, see the WasteMinz website.

Bags & Wrap – Pēke, Tākai

Bottles & Jars – Pātara, Ipu Karaehe (glass containers)

Cans – Kēne

Cardboard – Kāri Mārō

Clear – Kōataata

Containers – Ipu

Drink – Inu

Food Scraps – Para Kai

Food Scraps & Compostable Packaging – Para Kai, Tākai Pōpopo

Furniture – Taputapu whare

Garden Cuttings – Tapahanga Māra, Tapahitanga Māra

Glass – Karaehe Karāhe, Kōata

Landfill – Ruapara

Milk Bottles – Pātara Miraka

Paper – Pepa

Plastic – Kirihou

Polystyrene – Kirihou Kōmāmā

Recycling – Hangarua, Hakarua is Ngāi Tahu dialect for Hangarua

Reuse – Whakamahia Anō

Rubbish – Para, Rāpihi

Shopping Bags – Pēke Hokohoko

Soft Plastic – Kirihou Ngohengohe

MEDIA RELEASE: The cost of dealing with packaging waste and a crumbling international recyclables market has until now been paid by ratepayers, and ultimately by our environment.

29 July 2020

For this reason, the country’s biggest packaging industry group, The Packaging Forum, backs today’s packaging announcement by Associate Minister for the Environment Eugenie Sage. Under the Waste Management Act 2008, plastic packaging will be declared a priority product.

The declaration allows for new regulation that will require all importers, producers and retailers to take responsibility for their packaging under a product stewardship model.

The Forum’s Independent Chair Rob Langford says regulated stewardship is a highly effective way of dealing with packaging and is the most significant move to date by a New Zealand government.

“However, there are pitfalls” he says. “That’s why it’s crucial that solutions are developed and led by business, in consultation with other stakeholders,” says Rob. “Effective solutions require not just the right regulations, but the mechanisms, infrastructure and innovations that business can provide to solve challenges throughout a product’s life cycle.

“Successful product stewardship schemes are not just collections systems. They must address the entire life cycle of packaging material – including product design that minimises waste, collection systems, labelling that is clear and meaningful for consumers, onshore recycling infrastructure, through to gueniuine and valuable use of recycled products. A circular, evidence-based approach is critical.”

Packaging Forum members have been funding voluntary solutions for packaging for a number of years. This includes the only government-accredited schemes for glass bottles and jars, and for soft plastics, alongside delivering the public place recycling initiatives such as the Litter Less, Recycle More project.

“While our voluntary schemes have achieved great results,” Rob says, “regulation shouldallow us to step up the scale of impact by by allowing for the removal of free-riders – those brands that currently choose not to contribute.

“We will now work to transition our voluntary schemes to comply with new guidelines for regulated schemes when they are issued.

While beverage containers were not announced as a priority product today, they were included in the initial consultation.

There is a working group looking at a Container Returns Scheme (CRS) for beverage packaging, however we believe glass, which already has a recovery rate of over 70% and an established onshore recycling solution, should be excluded from any CRS. We are already working on an alternative whole of life cycle model for glass that we are confident will cost consumers substantially less than a CRS scheme.

“We also look forward to working with Ministry for the Environment, local government, the resource recovery sector, and key community groups on co-designed and regulated solutions for packaging types that currently have no stewardship scheme in place,” Rob says.

The Forum accepts there will be a cost to business and ultimately consumers, but believes doing nothing comes at a high price to our environment and future. With regulation bringing the entire industry to the table, they say solutions will be robust, efficient and cost effective. Most importantly, if well designed, they will deliver better environmental outcomes for New Zealand.

MEDIA RELEASE: The Government’s decision to expand and increase the waste levy is a bold and welcome move towards reducing the country’s reliance on landfills in favour of reuse, recycling and composting.

16 July 2020

This according to the country’s biggest member-based packaging organisation, The Packaging Forum. The Forum’s Independent Chair Rob Langford says it fully supports the decision and also welcomes the announcement of $124 million in Government investment in recycling infrastructure.

“This investment is a clear signal that Government is serious about working with industry to reduce waste and increase onshore recycling infrastructure that will create jobs for New Zealanders. It isn’t simply making it more expensive to dispose of waste but wants to develop solutions which decrease the amount of waste generated in the first place,” Rob says.

“This aligns with The Packaging Forum’s goal, which is to work with its over 200 member brands to help them make all their packaging reusable, recyclable or compostable by 2025.”

The Packaging Forum and the Glass Packaging Forum, a stewardship scheme run by The Packaging Forum, made submissions to the Ministry for the Environment earlier this year in support of the increased waste levy. “We are very pleased to see what has been announced aligns with our recommendations to the Minister,” Rob says.

The Packaging Forum operates three government-accredited voluntary product stewardship schemes – the Glass Packaging Forum, Soft Plastic Recycling Scheme and the Public Place Recycling Scheme.

Disincentivising waste through a higher levy, while using the funds generated from it to develop waste reduction projects and infrastructure is a sound approach to tackling New Zealand’s waste problem, he says.

While The Packaging Forum believes the same system of levying should apply across the board, it would also like to see a lower levy for specific by-products of recycling. “It’s important the levy doesn’t disincentivise recycling activity carried out within New Zealand, creating employment opportunities,” Rob says.

The Forum also encourages the Ministry to develop a national waste levy investment plan, focused on the recovery of recyclable resources, so there is transparency about priorities. Additionally, it believes the allocation system for funding should be reviewed so funding is based on projects and their impact, not on a per-capita basis.

“Investment needs to be smart and strategic to achieve the best possible resource recovery outcomes. This goes hand-in-hand with improved tracking and measuring of waste data through robust, independent and transparent methods.”

We look forward to working with the Ministry for the Environment on an investment plan for high quality, onshore resource recovery solutions, Rob says.