MEDIA RELEASE: The Public Place Recycling Scheme‘s annual report is now available.

19 June 2020

Funding application for 2024 – 2025 are now open Apply Now

Member Portal

Not a member? Join us here

MEDIA RELEASE: The Public Place Recycling Scheme‘s annual report is now available.

19 June 2020

MEDIA RELEASE: There’s little doubt New Zealand’s environmental credentials as a clean, green country are under threat.

5 June 2020

With one of the highest per-capita urban waste disposal rates in the world it’s clear we aren’t leading in terms of waste reduction – yet. While it’s easy to point the finger at consumers, it’s producers that have even more responsibility, and the ability, to pivot away from the take-make-waste, linear economy. This will in turn give consumers the ability to support a sustainable, efficient and regenerative circular economy.

The key means to achieving this is through extended producer responsibility (EPR). So, what is EPR and how is it different from product stewardship?

It’s a practice whereby importers and producers of products bear a significant level of responsibility for the impact their products have on the environment, not just at the end of their life, but throughout their lifecycles.

This involves upstream impacts like the selection of materials for the products, and impacts from the production process. It also includes downstream impacts from the distribution, use and disposal of the products and packaging.

Producers practicing EPR design their products to be environmentally friendly throughout their life cycles. They accept legal, socioeconomic or physical responsibility for environmental impacts that cannot be removed by design.

If this is sounding strikingly similar to product stewardship, it’s because the two are technically the same thing – in that producers take responsibility for the products they make and sell at end of life. However, EPR takes a broader approach to the material being used.

The cost of recovering and reusing, recycling or properly disposing of a product at the end of its life needs to be equally distributed through the supply chain. In other words, the material must own the cost of its recovery.

EPR assesses the lifecycles of the materials being used with the aim of ensuring they are cradle to cradle and challenging the use of materials which are cradle to grave. This approach drives product design centred on easy recovery and reuse or recycling as well as more efficient resource use.

Every material is different and simply overlaying a source separation collection model such as a container return scheme (CRS) will have unintended impacts, unless the full material balance is clearly understood.

It’s about understanding that creating less waste isn’t simply about using less, or maximising recycling rates, it’s about avoiding waste through smarter design and improved efficiency. It’s time to challenge the concept of waste reduction and pivot thinking to maximising resource value.

The packaging industry supports a move to an environment which drives the right material use and recovery behaviours, as well as a framework which provides clarity for investment. We also recognise that Government has a role to play in putting in place effective, evidence-based policies and regulatory drivers to support development. Industry has the innovation and expertise to take the lead in shaping solutions that work. But it takes collaboration.

The Glass Packaging Forum’s (GPF) government-accredited product stewardship scheme for glass bottles and jars is an example of moving towards effective EPR. Producers not only take responsibility for the glass containers they make, import and sell, but invest in efficient design such as bottle light-weighting, and using glass which falls into the three colours which can be recycled (clear, brown and green).

The next logical step towards true EPR isn’t simply about effectively recycling glass made from virgin material, but rather producers choosing to use glass containers which already have a substantial recycled component. This way the issue of using virgin material is addressed in favour of a cradle to cradle, circular, flow of resources.

Some producers also support and encourage the refilling of containers where possible, with the product and system design key factors in enabling easy reuse.

The GPF is an example of stewardship working. It’s also an organisation that’s evolving its own model, with a focus on how to deliver a fully costed cradle to cradle EPR solution for glass.

The Packaging Forum, together with our members, is working hard to enable the industry to pivot towards EPR solutions. At the core of this is the Forum’s Pledge 2025 in which we are working towards comprehensive stewardship solutions delivered by industry, in partnership with the whole supply chain, including local and central government and communities, so all packaging will be reusable, recyclable or compostable by 2025.

We hope you will join us as we strive together for a packaging waste-free New Zealand.

The Glass Packaging Forum (GPF) has released its 2018-2019 annual accreditation report highlighting the performance of glass recovery nationally, including recycling, mass balance data, funding, and stakeholder engagement.

2 June 2020

The report is an annual requirement of its Government accreditation and demonstrates industry’s long-term stewardship of glass.

GPF Scheme Manager Dominic Salmon says work was focused on consolidating gains made over the previous year, particularly removing barriers to glass recycling through improvements to infrastructure, with two primary areas of focus. These being financially supporting improved glass recycling outcomes through grants, and building relationships between glass packaging manufacturers, importers, fillers, and sellers and those who collect and recycle glass.

“Our success this year was due to relationships with our members, councils, community groups, transport operators and end market users,” Dominic says.

“Profile is critical to the scheme’s success and every effort has been made to promote the infinitely recyclable nature of glass right here in New Zealand.”

Mass balance for the year showed a total glass capture rate of 73% of all glass going to market. Of this 71% was recycled – a 9% increase on the previous year – while 14% went to roading, 6% was stockpiled and 7% went to landfill.

Data improvement was a major focus this year, and will remain so, but with the scheme being voluntary it’s accepted the whole picture cannot be known. “As a voluntary scheme there is no obligation for the relevant parties to provide the required data, so it’s an on-going challenge to ensure the majority of glass handled at the various points of its life cycle are accounted for,” Dominic says. “However, we continue to look at ways we can improve our data quality.”

As part of a ‘let’s talk’ approach the GPF achieved a survey engagement response rate of over 60% from both industry and local government. This saw the scheme achieve its 2024 target for survey engagement rates.

Grant allocations were focused on “sensible infrastructure” such as glass storage bunkers and collection of glass for recycling to improve transport efficiency and viability. In total $457,983 was funded for projects ranging from infrastructure to public place recycling, plant and research. This funding helped improve the flow of 11,000 tonnes of glass.

Dominic says he is pleased with progress and believes the scheme is on track to achieving its future goals, most notably a glass capture rate of over 80% by 2024. “Our current 73% recovery rate is enviable for any material in any part of the world, but by continuing to work with stakeholders we are confident of achieving more.”

Read the full report.

As part of our members’ commitment to taking responsibility for their packaging throughout its lifecycle, we’re inviting expressions of interest from members with special expertise or knowledge to join us in forming two technical advisory groups – one for compostable packaging, and another for fibre packaging (card and paper).

28 May 2020

Each of these packaging types has unique challenges when it comes to end of life resource recovery, be it collection, processing or end markets. Sound, scalable solutions will require input from those within the industry as well as others with specialist technical knowledge.

The Packaging Forum had previously formed a working group that was investigating the possible adoption of a compostable packaging standard. This group was disbanded pending the results of research being carried out on compostability of materials by other parties. The scope of the new advisory group will likely extend beyond establishing a standard.

The groups will explore the barriers and possible pathways to end of life solutions for these packaging types. Their findings and advice will inform decisions made by The Packaging Forum board. The terms of reference for the advisory groups will be established at the first meeting of interested parties. The Packaging Forum is committed to continue working collaboratively with other industry groups on these issues.

If you are interested in becoming a member of either of the groups, please register your expression of interest with Adele Rose (adele@packagingforum.org.nz) by 15 June 2020.

The Soft Plastic Recycling Scheme has published its first Accreditation Report, for the period from 1 April 2018 to 31 December 2019.

28 May 2020

The Packaging Forum set up soft plastics collections in 2015 and the soft plastic recycling scheme received accreditation as a voluntary product stewardship scheme under the Waste Minimisation Act in March 2018.

Chair of the scheme Malcolm Everts says that the scheme is a genuine example of a circular economy which directly funds collection, transport and processing: “The report shows a tale of two different years and reflects the massive changes in global recycling conditions. Different times need different approaches and we have evolved from collecting as much as possible and shipping it to offshore recyclers, to collecting what we can process here in Aotearoa. Local processing is critical, and we have built close partnerships with Future Post and Second Life Plastics.”

“We adapted the scheme to match collections with NZ processing capacity, plus we have put further focus on reduce and re-use initiatives like phasing out single use plastic bags. It is pointless collecting waste if there is nowhere to recycle it. In 2019, around 13 million bags, enough to fill an Olympic sized swimming pool were collected and recycled in New Zealand, and that’s without the shopping bags that have been banned. This is in contrast to 2018 when 100 million bags were dropped off for recycling, but overseas recycling markets dried up and we stopped collections temporarily to deal with the excess.”

Mr Everts added: “Product stewardship schemes must be flexible to adapt to the economic and environmental climate. Kiwis are engaged, and happy to clean, collect & deliver material for recycling. Industry is engaged under a voluntary approach and around 70% of brands that use soft plastic are scheme members funding the recycling service and taking steps within their own businesses to reduce plastic consumption where feasible.”

Scheme Manager Lyn Mayes agreed that flexibility and loyalty has been critical:

“Since the scheme received accreditation in March 2018, we first had to deal with the impact of China’s National Sword Policy which resulted in us suspending collections in early 2019 and this year we again suspended collections during COVID-19 lockdown. Throughout these changing times, I would like to thank the ongoing support and loyalty of our members, collection and processing partners and consumers.”

The report concludes that the principal limiting factor for the scheme is that there are only two processors in the North Island which are able to process post-consumer soft plastics and notes that expansion of processing capacity requires:

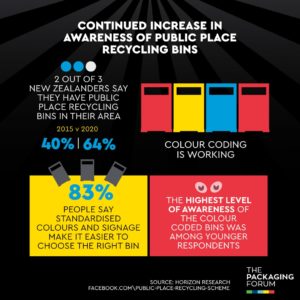

New Zealand is winning the war on litter, a recent survey shows, with more people aware of public bins, more likely to put litter and recycling in the correct bin, and feel litter is less of a problem in their area.

20 April 2020

The survey, conducted by Horizon Research for The Packaging Forum, spoke to over 1000 people about the Forum’s Public Place Recycling Scheme bins and the Love NZ brand. It found that some 2.3 million adults have public place rubbish and recycling bin in their area.

Public Place Recycling Scheme Manager Lyn Mayes says the statistics are very encouraging. “Two out of three New Zealanders (64%) say they have public place rubbish and recycling bins in their area – up from 40% in 2015.

“We have worked hard with councils and businesses around New Zealand to increase ‘binfrastructure’ and to introduce standardised colours and signage to make it that much easier for people do the right thing and put litter or recycling in the correct bin. It’s great to know it’s working.”

The number of young adults (18-24 years-old) aware of the scheme’s new colour-coded bins, or who have public place recycling bins in their area is a good sign for the future, Lyn says. The survey showed 79% of them have bins in their area and 75% are aware of the new bins.

The colour-coded bins were introduced in 2017 as part of the nationwide Let’s Put Litter in its Place campaign run in partnership with Be a Tidy Kiwi, are having an impact, Lyn says.

“Eighty-three percent of people in the survey say standardised colours and signage make it easier to choose the right bin when throwing away rubbish or recycling while they are out and about.”

The survey shows there is a corresponding decrease in people’s concern around the amount of litter in their area. “This has dropped significantly from 44% in 2019 to 29% this year,” Lyn says.

“Our awareness campaign has seen thousands of Kiwis, including the Prime Minister, politicians and celebrities, pledge to ‘Be a Tidy Kiwi’ and stop littering. It’s rewarding to see that one in three understood the idea behind the campaign and would now ask someone to pick up litter if they saw someone drop it, while a similar number would pick litter up themselves.”

Women, she says, were shown to be more like than men to ask someone to pick up litter.

Not all the statistics showed improvements. People’s willingness to walk a short distance to find a bin had changed little, with 79% prepared to walk more than 10 metres – the same as 2019.

However, there was an increase in the number of people prepared to walk more than 40 metres to find a bin, with 37% saying they would – up from 29% in 2019 and 23% in 2018.

Foodstuffs and Prolife Foods are trialling a new, recycled paper packaging solution in the Alison’s Pantry departments of 30 stores.

25 February 2020

The recycled paper bags are on trial at 30 New World and PAK’nSAVE stores around the country until the end of March. This option will be available alongside the existing Alison’s Pantry resealable LDPE (type 4) bags.

Read more: Supermarket News article

The Collective, is leading the charge as the first yoghurt company in New Zealand to use recycled plastic (rPET) in its packaging.

26 February 2020

As part of a company-wide sustainability journey to reduce its environmental impact, The Collective’s kefir probiotic yoghurt is the first of its products to hit the shelves with recycled plastic packaging.

Read more: Supermarket News article

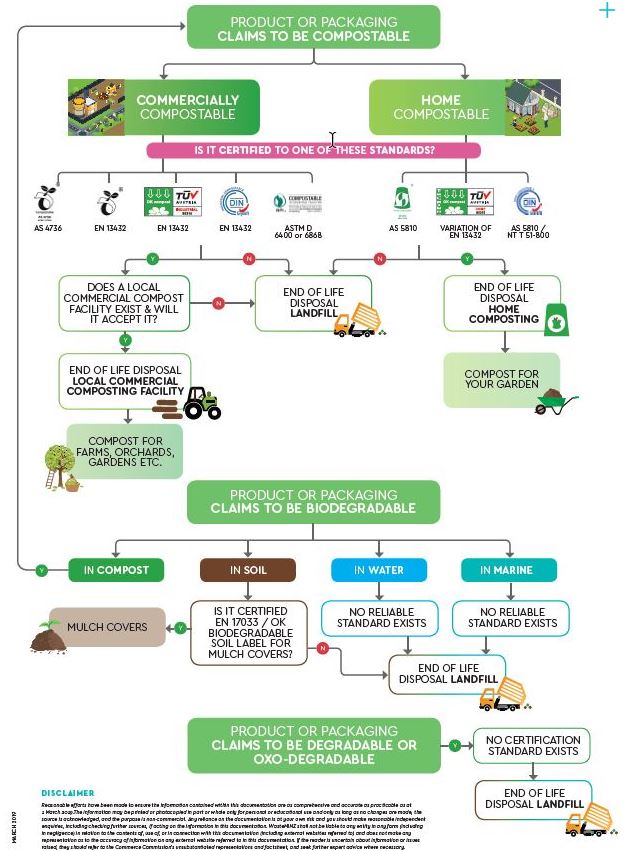

Plastics New Zealand’s CEO Rachel Barker has called for a crackdown on a practice called ‘greenwashing’ – where manufacturers claim their products are renewable or plastic free when they aren’t.

“There is a high level of greenwash around packaging in New Zealand, such as claims of ‘I’m not plastic’ on bags and bottles which are still plastic, even when they’re compostable or made from plants. Other items are advertised as ‘renewable’ when they include oil-based plastics. With the public increasingly concerned about making sustainable shopping purchases, this kind of greenwashing needs to stop.”

Ms Barker says that the definition of what is or isn’t a plastic is very clear.

“Plastic is any material that’s made from very long molecule chains called ‘polymers’ that can be formed into a shape and set. They can be made from plants like corn or sugar-cane as well as fossil-fuels. Plastics that are compostable are still plastic.”

WasteMINZ believe the key to stopping the greenwash is by providing clear guidance for consumers and product suppliers in New Zealand. Chris Purchas, chair of the WasteMINZ Organic Materials sector group, notes that:

“A lot of these materials are quite new and there hasn’t been a lot of guidance around advertising. Companies may accidentally mislead their customers and don’t realise their claims fall foul of the Fair Trading Act.”

WasteMINZ and Plastics NZ have set out to change this and have created the Guide to Advertising the Plastics Used in Compostable Products and Packaging. This was developed in collaboration with scientists, composting specialists and compostable packaging manufacturers. It answers some important questions and helps clear up the confusion for both companies and consumers.

The guide also tackles the myth that all plant-based plastics (bioplastics) are compostable. Rachel Barker points out,

“There is confusion around what is and isn’t compostable. Just because packaging is made from plants doesn’t automatically mean it’s compostable. Conversely packaging made using fossil fuels, isn’t automatically non-compostable.

Being compostable also doesn’t necessarily mean the item is made from renewable materials. It means the item will be converted to compost under the right conditions and the only way to definitively know is through a proper verification process. That’s why composting certification is so important.”

WasteMINZ and Plastics NZ encourage producers and brands to upskill so they can avoid landing in trouble with the Commerce Commission. The guideline can be downloaded here.

A list of the most common bioplastics on the market at the moment and whether they are plant-based or oil-based and whether they can be recycled or composted can be found here.

Leading beverage company Frucor Suntory has taken another significant

step in its commitment to sustainable production with the introduction

of 750ml glass bottles for its NZ Natural still and sparkling water.

30 August 2019

The sustainable and 100 per cent recyclable packaging is the latest in the Frucor Suntory’s commitment to plastic reduction, following the company’s promise to make 100 per cent of it’s packaging recyclable or reusable by 2025.

Read more: Hospitality Business article