Funding application for 2025 – 2026 are now open Apply Now

Member Portal

Not a member? Join us here

Final submissions can be found below

24 November 2021

The government has been consulting on a discussion document for a plan to transition to a low emissions and climate resistant future.

The Packaging Forum sought member feedback on its draft submissions.

Final submissions can be found here.

The country’s largest packaging industry group has welcomed Government’s move to phase-out difficult-to-recycle and some single-use plastics.

29 June 2021

The Packaging Forum CEO Rob Langford says the Forum, and its Soft Plastic Recycling Scheme (SPRS), had largely supported the proposal during its consultation period, and were pleased to see Government take the next step.

“There was a long consultation period, as there should be, and it’s great to see Government moving forward. It’s essential there are end-of-life solutions in place for packaging and in the case of the plastic types being phased out that is not the case.

“Oxo-degradable plastics are a prime example as they are neither recyclable or compostable,” Rob says. He added that it’s important to note bio plastics (often referred to as ‘compostable plastic’) will also be part of the single-use plastic item phase-out.

The Forum cautioned against the phase-out causing unintended consequences. As industry moves to alternative materials there must also be the development of recycling, reuse and other end-of-life solutions for these materials, as well as consideration around food safety, Rob says.

“We are therefore urging care when choosing alternatives,” he says.

Rob pointed out alternative materials, such as compostable and fibre (paper and cardboard) packaging also have challenges, especially when we consider New Zealand’s focus on a low-emissions and zero waste economy.

“Our Compostable Technical Advisory Group is currently developing a use-case for New Zealand and is busy consulting with industry and stakeholders,” Rob says.

Moving to alternative materials is a major undertaking for a lot of manufacturers, importers and retailers, he says.

The Forum’s submission during the consultation period called for a full cost benefit analysis, which follows Treasury guidelines, to assess impact on business, food safety, shelf life and cool-chain (particularly for export items).

“That’s where the $50 million Plastics Innovation Fund announced by Government is therefore very welcome and will be vital in helping industry transition and overcome challenges. We are watching with interest to see how those funds will be allocated and excited to see what innovative solutions are developed as a result.”

Phase-out timeline:

By late 2022:

By mid-2023:

By mid-2025:

Please join us to discuss this important topic

11am – 12 noon

Mon 28 September

Lyn Mayes, Scheme Manager of our Soft Plastics Recycling Scheme will talk about recycling coverage and recyclability thresholds.

Dana Paterson from the Ministry for the Environment will provide an overview of the regulatory framework and a 101 on what being priority product means.

MEDIA RELEASE: The Packaging Forum welcomes Government’s latest move to phase-out difficult to recycle and unnecessary plastic packaging.

12 August 2020

However, the Forum’s Independent Chair Rob Langford cautions that great care must be taken to avoid any unintended consequences caused by producers and retailers moving to other packaging types such as a mass shift to compostable packaging without standards, labelling and end-of-life solutions being in place.

The Forum was reacting to the announcement by Associate Minister for the Environment Eugenie Sage today (12 August) that consultation would begin on the phase-out of a number of plastic products, such as straws, PVC food and beverage packaging, plastic tableware, and plastic cotton-buds among others.

Consultation would run until 4 November 2020.

“It’s good to see there is a long consultation period for this and we’ll certainly be part of the conversation on behalf of our members,” Rob says. The Packaging Forum, with more than 200 members, is New Zealand’s biggest member-based organisation representing the depth and breadth of the packaging industry.

While compostable packaging can be viewed by the public as something of a ‘silver bullet’, Rob warns there are also challenges with it. “For manufacturers, there is no defined use-case for compostable packaging.

“There is no New Zealand standard as required by the organic certified composters and few commercial composters which will accept it due to contamination, and there are varying requirements for home compostability. This makes it difficult for consumers to identify how to dispose of it at end of life.”

To assist members, the Forum has a compostable packaging and a fibre-based packaging technical advisory group which is investigating solutions for these challenges to remove the barriers for compostable packaging across the supply chain, Rob says.

“We welcome the opportunity to submit during the consultation period. Our members will be able to offer their knowledge and know-how to help ensure we have the best possible outcome.”

With recent regulation of plastic packaging as a priority product, all producers and importers of goods in plastic packaging will have to get on board with product stewardship. What does that mean for business? Rob Langford, Independent chair of The Packaging Forum explains.

4 August 2020

Business isn’t known for welcoming government regulation, but the news that plastic packaging will be regulated is cause for celebration by all of us who care about our impact on our environment.

That includes businesses already contributing to better environmental outcomes for their packaging and shouldering the cost through voluntary stewardship schemes. Regulation allows for the removal of ‘free-riders’ – businesses which have previously not participated.

Now all Importers, manufactures and brand owners whose goods use plastic packaging will have to contribute to schemes that address its environmental impact. So work begins designing what effective regulated product stewardship looks like in New Zealand. The Packaging Forum members are up for the challenge.

Where packaging already has a voluntary stewardship scheme, (such as The Packaging Forum’s Soft Plastic scheme), they can work to transition to a regulated model. With everyone on board, the opportunity to scale up the impact with more comprehensive solutions is exciting. For packaging types where no scheme exists (e.g. rigid plastic packaging), they will have to be designed.

We are looking forward to working on behalf of our members with the Ministry for the Environment, local government, the resource recovery sector and key community and industry groups on scheme co-design.

I believe there are clear criteria that contribute to success for a product stewardship scheme.

Whole of life cycle, circular approach

The most successful schemes don’t just deal with end-of-life solutions and aren’t just collection systems. They have whole life cycle approach. They encourage product design that removes unnecessary packaging and promotes materials which have a higher recycling value. Other aspects of the life cycle they can address are effective collection, processing infrastructure and demand for material with a high recycled content. In some cases, reusable or refillable packaging may be part of the answer.

Our Soft Plastic Recycling scheme highlights the importance of this approach. When popularity with consumers and collections quickly outgrew processing capacity, the scheme had to be temporarily suspended. New processors were found onshore who worked to develop end markets for their recycled products. The scheme is now back up and running in 74 locations across the North Island, and looking to expand further as new processing capacity develops.

Business led

Regulation simply sets the scene for solutions. Business will provide the mechanisms, infrastructure and innovation for them to be carried out. Business must lead the co-design of schemes in collaboration with local and national government, the resource recovery sector and key community groups.

Our Glass Packaging Forum scheme has shown that collaboration with key stakeholders for investment in pragmatic solutions can have a big impact. Our grant funding to bolster efficiencies in the South Island saw over 340% growth in the volume of glass returned for recycling through one processor alone between 2017 and 2019. It’s investment like this that has helped it reach a recovery rate of over 70% of container glass for recycling and reuse.

Easy for consumers

While there will always be people who choose not to recycle, the more convenient it is, the more likely they are to do it. Whether it’s access to kerbside recycling, clear and useful recyclability labelling, or colour-coded recycling bins in public places, consumer engagement is a must-have in any stewardship scheme.

Onshore solutions

We’ve seen what happens when there is too much reliance on overseas recyclables markets. A lack of onshore capacity left New Zealand and much of the world exposed and sending recyclables to landfill when other countries effectively shut the door. Taking responsibility for our own packaging onshore isn’t just the right thing to do, it’s an investment in employment opportunities and New Zealand’s economic resilience.

The right packaging choices protect our food, our goods, and us. Now we have an opportunity for those choices to keep our environment safer from harm too.

MEDIA RELEASE: Single-use plastic beverage containers, such as plastic bottles, are included in the Government’s latest announcement to tackle the country’s poor record on waste reduction, says The Packaging Forum Independent Chair Rob Langford.

30 July 2020

His comment is in response to Greenpeace’s statement shortly after the announcement they were disappointed, “the new scheme doesn’t tackle one of the country’s biggest plastic pollution problems – single-use drinks bottles.”

The Packaging Forum is the country’s biggest packaging industry member-based organisation.

The remarks follow the announcement by Associate Minister for the Environment Eugenie Sage that six product categories, including plastic packaging, have been declared priority products under the Waste Minimisation Act. This triggers the creation of regulated product stewardship schemes to manage these products throughout their lifecycle, especially at end of life through reuse, recycling or proper disposal.

Rob says single-use plastic beverage containers do fall under the category of ‘plastic packaging’ announced by the Minister. “It’s important to understand no regulated product stewardship schemes have yet been established for the multitude of packaging types which are affected.

“A container return scheme is being developed as a possible option for stewarding beverage containers, which I am involved in, but the group working on this is yet to report to the Ministry. The announcement made by Minister Sage was about what would be included in regulated stewardship schemes, not how they would be stewarded.”

The Forum had welcomed the announcement as regulated stewardship is a highly effective way of dealing with packaging and is the most significant move to date by a New Zealand government in the war on waste, Rob says.

“Successful product stewardship schemes are not just collections systems. They must address the entire lifecycle of packaging material – including product design that minimises waste, collection systems, labelling that is clear and meaningful for consumers, onshore recycling infrastructure, through to genuine and valuable use of recycled products. A circular, evidence-based and industry-led approach is critical,” he says.

MEDIA RELEASE: The Government’s announcement to regulate product stewardship for single-use plastic packaging is broadly supported by the Soft Plastics Recycling Scheme.

29 July 2020

The Packaging Forum set up soft plastics collections in 2015 and the scheme received accreditation as a voluntary product stewardship scheme under the Waste Minimisation Act in March 2018.

Chair of the scheme Malcolm Everts says that the collapse of global markets for mixed plastics forced a major re-set of the scheme in 2019 and this has been further influenced by COVID-19 limiting collections and processing for a period of time.

“Our scheme is focused on supporting local processors. Two years ago, there was no onshore processing of post-consumer soft plastics. Today there are two North Island plants Future Post in Waiuku and Second Life Plastics in Levin which are great examples of Kiwi ingenuity and we are increasing every month the tonnes which we send for recycling.

“With the expansion of their capacity we can now offer soft plastic recycling to around 60% of the population with drop off points across Auckland, Waikato, Northland, Bay of Plenty and Wellington. We will be adding more stores in more regions throughout the year.”

“As a voluntary scheme, we already have over 70% of industry by volume funding the recycling programme and membership has increased by 20% in the past year to 75 companies. We are also working with members on the design of their packaging, reducing creation of plastic packaging waste, and advocate using our “return to store” labelling system.”

“Scheme members’ levies fund collections from stores, quality checks, baling, transport to end markets and contribute to the processing costs as well. This is different from the traditional model where the processor pays the collector/recycler for the materials, so we are well prepared to transition to a regulated scheme model.”

“We hope to see soft plastic recycling processing projects funded in this year’s Waste Minimisation Funding Round and through the proposed $124 million investment in recycling announced by the Government earlier this month. It is only with a substantial increase in processing capacity including the South Island that the Scheme can deliver its full potential”

“We will work with the Ministry for Environment to develop a sensible co-design process to transition our voluntary product stewardship scheme to meet the new regulations over the next three years. In the meantime, it is business as usual for our scheme.”

MEDIA RELEASE: The cost of dealing with packaging waste and a crumbling international recyclables market has until now been paid by ratepayers, and ultimately by our environment.

29 July 2020

For this reason, the country’s biggest packaging industry group, The Packaging Forum, backs today’s packaging announcement by Associate Minister for the Environment Eugenie Sage. Under the Waste Management Act 2008, plastic packaging will be declared a priority product.

The declaration allows for new regulation that will require all importers, producers and retailers to take responsibility for their packaging under a product stewardship model.

The Forum’s Independent Chair Rob Langford says regulated stewardship is a highly effective way of dealing with packaging and is the most significant move to date by a New Zealand government.

“However, there are pitfalls” he says. “That’s why it’s crucial that solutions are developed and led by business, in consultation with other stakeholders,” says Rob. “Effective solutions require not just the right regulations, but the mechanisms, infrastructure and innovations that business can provide to solve challenges throughout a product’s life cycle.

“Successful product stewardship schemes are not just collections systems. They must address the entire life cycle of packaging material – including product design that minimises waste, collection systems, labelling that is clear and meaningful for consumers, onshore recycling infrastructure, through to gueniuine and valuable use of recycled products. A circular, evidence-based approach is critical.”

Packaging Forum members have been funding voluntary solutions for packaging for a number of years. This includes the only government-accredited schemes for glass bottles and jars, and for soft plastics, alongside delivering the public place recycling initiatives such as the Litter Less, Recycle More project.

“While our voluntary schemes have achieved great results,” Rob says, “regulation shouldallow us to step up the scale of impact by by allowing for the removal of free-riders – those brands that currently choose not to contribute.

“We will now work to transition our voluntary schemes to comply with new guidelines for regulated schemes when they are issued.

While beverage containers were not announced as a priority product today, they were included in the initial consultation.

There is a working group looking at a Container Returns Scheme (CRS) for beverage packaging, however we believe glass, which already has a recovery rate of over 70% and an established onshore recycling solution, should be excluded from any CRS. We are already working on an alternative whole of life cycle model for glass that we are confident will cost consumers substantially less than a CRS scheme.

“We also look forward to working with Ministry for the Environment, local government, the resource recovery sector, and key community groups on co-designed and regulated solutions for packaging types that currently have no stewardship scheme in place,” Rob says.

The Forum accepts there will be a cost to business and ultimately consumers, but believes doing nothing comes at a high price to our environment and future. With regulation bringing the entire industry to the table, they say solutions will be robust, efficient and cost effective. Most importantly, if well designed, they will deliver better environmental outcomes for New Zealand.

Plastics New Zealand’s CEO Rachel Barker has called for a crackdown on a practice called ‘greenwashing’ – where manufacturers claim their products are renewable or plastic free when they aren’t.

“There is a high level of greenwash around packaging in New Zealand, such as claims of ‘I’m not plastic’ on bags and bottles which are still plastic, even when they’re compostable or made from plants. Other items are advertised as ‘renewable’ when they include oil-based plastics. With the public increasingly concerned about making sustainable shopping purchases, this kind of greenwashing needs to stop.”

Ms Barker says that the definition of what is or isn’t a plastic is very clear.

“Plastic is any material that’s made from very long molecule chains called ‘polymers’ that can be formed into a shape and set. They can be made from plants like corn or sugar-cane as well as fossil-fuels. Plastics that are compostable are still plastic.”

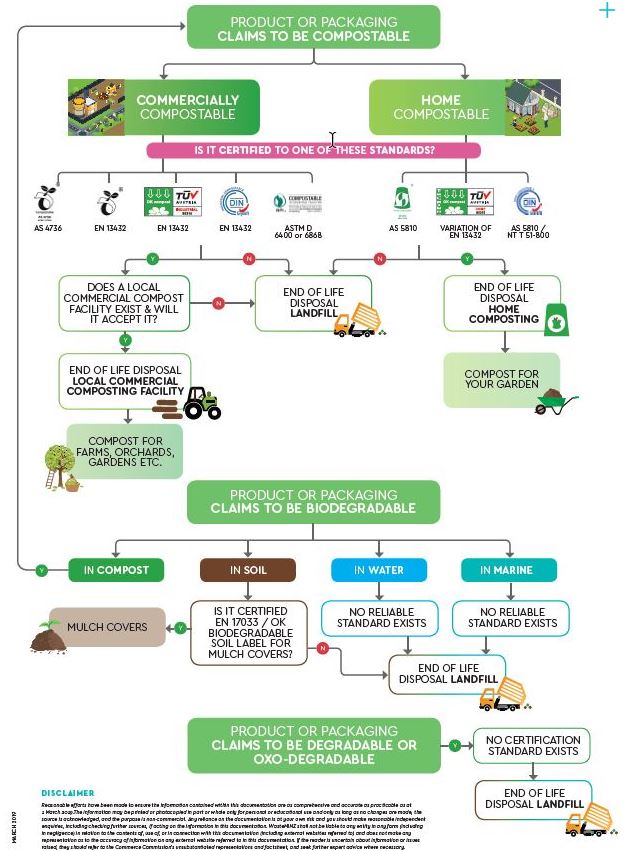

WasteMINZ believe the key to stopping the greenwash is by providing clear guidance for consumers and product suppliers in New Zealand. Chris Purchas, chair of the WasteMINZ Organic Materials sector group, notes that:

“A lot of these materials are quite new and there hasn’t been a lot of guidance around advertising. Companies may accidentally mislead their customers and don’t realise their claims fall foul of the Fair Trading Act.”

WasteMINZ and Plastics NZ have set out to change this and have created the Guide to Advertising the Plastics Used in Compostable Products and Packaging. This was developed in collaboration with scientists, composting specialists and compostable packaging manufacturers. It answers some important questions and helps clear up the confusion for both companies and consumers.

The guide also tackles the myth that all plant-based plastics (bioplastics) are compostable. Rachel Barker points out,

“There is confusion around what is and isn’t compostable. Just because packaging is made from plants doesn’t automatically mean it’s compostable. Conversely packaging made using fossil fuels, isn’t automatically non-compostable.

Being compostable also doesn’t necessarily mean the item is made from renewable materials. It means the item will be converted to compost under the right conditions and the only way to definitively know is through a proper verification process. That’s why composting certification is so important.”

WasteMINZ and Plastics NZ encourage producers and brands to upskill so they can avoid landing in trouble with the Commerce Commission. The guideline can be downloaded here.

A list of the most common bioplastics on the market at the moment and whether they are plant-based or oil-based and whether they can be recycled or composted can be found here.