Aspect Productivity Technology is helping its clients achieve greater sustainability through smart technology, which provides better quality information for informed decision making.

24 November 2020

Aspect Productivity Technology is helping its clients achieve greater sustainability through smart technology, which provides better quality information for informed decision making.

24 November 2020

Sustainability is about meeting the needs of today, without adversely impacting on the needs of tomorrow. Sustainability in manufacturing is achieved with new or improved technologies alongside sustainable business philosophies and models.

Achieving greater sustainability is also not just about production efficiencies, minimising waste and maximising resources. A well-run digital manufacturing floor helps manufacturers become more sustainable by enabling faster access to better quality information for informed decision making.

Aspect Productivity Technology, a member of The Packaging Forum, explains how their Manufacturing Execution System (MES) is doing just that, and helping its packaging customers become more sustainable.

Bonson Packaging’s sustainability philosophy

Sustainability is an important goal at Bonson Packaging in Auckland. They support a circular economy with an offering of recyclable, bio-degradable and compostable products.

The company promotes a reduce, reuse, recycle and recover philosophy and applies these practices to its operations.

An example of this is Bonson using data from the AspectPL MES software to monitor the power usage of their machines. Machine output might be the same, but power usage can fluctuate. Data from AspectPL helps Bonson reduce electricity costs and its carbon footprint.

According to Bonson, the data supplied by AspectPL has helped reduce machine power use by 5% – giving their products a smaller carbon footprint.

Proficiency allows time for efficiency, reducing downtime and waste

Cormack Packaging has saved so many man hours since it implemented an MES, it now has time to concentrate on optimising production.

“Previously our planning information wasn’t totally accurate. We’d count boxes off the machine. The machine makes the product, we pack boxes, we count the number of boxes made.

“With AspectPL we have full visibility and real-time reporting on what’s actually happening. You can easily move jobs from machine to machine and look at ‘what if’ scenarios. The AspectPL scheduler has also saved us two days per month planning 250 work orders,” says Production Manager Shaun Wallace.

“Now I can work with the guys on the factory floor to optimize production. Currently we are working on making our changeovers faster, improving our line start and line clearance downtimes, and reducing waste. With AspectPL we can see these stats at the push of a button – and in real time.’’

Monitoring and measuring manufacturing processes not only reduces waste and improves productivity. It also helps businesses pursue sustainability through better quality information that supports long-term business viability.

Aspect Productivity Technology Ltd

Aspect Productivity Technology Ltd is an Auckland-based SaaS software company. Its product AspectPL is an MES (Manufacturing Execution System) specifically designed for plastics and packaging manufacturers.

AspectPL customers gain the practical benefits of having digital data available on their manufacturing floor. They also use the data analysis and insights to achieve their sustainability philosophies.

New Zealand-owned and run food box company and Soft Plastic Recycling Scheme member Woop has rolled out their ‘Back to Base’ product stewardship programme across all of their delivery areas.

19 October 2020

The scheme sees customers return their clean and dry packaging so it can be sorted and recycled.

Woop Founder Thomas Dietz says customers have been very enthusiastic about the initiative, as demonstrated by the high level of participation in the programme. “Customers appreciate the certainty the programme provides in knowing that the packaging is being properly recycled in New Zealand.”

We chatted to him to find out more about the company and its sustainability work.

Tell us a bit about Woop – how it started and what you hope to achieve.

Since Woop started five years ago we have placed a huge focus on our commitment to the environment and we’re excited by what we can continue to do to improve.

We brainstorm and create globally inspired recipes and select and prepare ingredients using the finest local produce, ahead of time, so our customers receive beautiful ingredients and hand-crafted sauces right to their door.

The company clearly has a strong focus on sustainable practices, tell us a bit more about that.

One hundred percent of our packaging is now recyclable or compostable, and we take responsibility for that through our Back to Base programme. But our commitment to sustainability goes further than that. We see our locally sourced ingredients, portion control to avoid food waste, and delivery emissions offsetting as essential parts of our sustainability focus too.

What is the drive behind this?

As a team we are committed to reducing our impact on the environment and as a values-led business we are very passionate about it. We want to make sure that we are doing more than just our part and take responsibility to continually improve.

Was sustainability always part of the Woop business plan, or did it develop over time?

We’ve always had sustainability as a core focus of our values, however how we have engaged and implemented changes and improvements has definitely developed over time as we have learnt more.

What have been/remain the most challenging packaging items to make sustainable?

The sachets were the most challenging, as they aren’t able to be recycled through kerbside recycling. However, by partnering with Future Post we are now able to recycle them.

We have now been able to find an end-of-life recycling solution for all of our packaging. This took a lot of research.

Would you say your focus on sustainability is a point of difference or something which is becoming something of standard practice?

We see our concrete sustainability actions and our unique Back to Base product stewardship programme as a point of difference.

How do you engage with your customers to encourage them to deal with your packaging responsibly?

We are fortunate to have a direct relationship with our customers and are able to engage with them directly via phone and email.

This allows us to communicate the importance of collaborating with them on how to properly recycle the packaging they receive. This direct relationship also allows our customers to easily provide feedback and suggestions.

How have you approached sustainability with your suppliers and what are the biggest challenges there?

We require our suppliers to share their plans on improving their own sustainability and support them to make the changes we require to be more sustainable. For example, reducing packaging used in the supply chain and reducing food wastage.

What do you see as the biggest challenges for packaging sustainability overall?

Education is a big challenge. It’s really important for the public to understand the full picture when it comes to the environmental impacts of using, and not using packaging, for food.

At the moment it can be confusing for customers as to what to do with used packaging and how to make sure it’s properly recycled. There is also a lack of understanding on the functional benefits packaging brings in reducing food waste.

Do you think ‘groceries as a service’ – where many locally-based companies supply locally-sourced, regional, ready to cook produce to customers – will ever come to rival or even overtake traditional supermarkets?

These types of services are becoming more and more popular and we believe this new way of eating will continue to grow as people get busier and look to outsource parts of their lives.

What do you think the future holds for Woop in terms of business growth and the sustainability challenges that brings?

We are excited by the challenges ahead with running our Back to Base programme and being able to continue to run this initiative as the number of weekly deliveries grows. We are also continually looking for other areas we can improve and act on.

What motivated you to join The Packaging Forum?

We were motivated to join the Forum for the support network it provides and the connections it has in the recycling industry.

These videos from Countdown explain some of the issues with plastics that you’ve been asking questions about:

5 July 2019

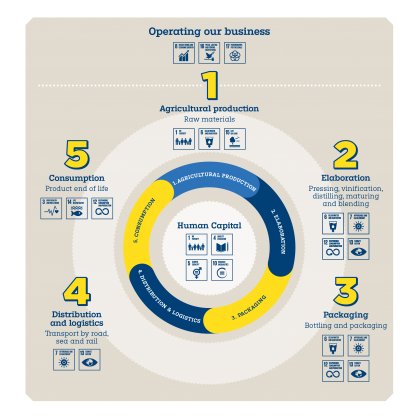

In April 2019 Pernod Ricard launched its 2030 Sustainability & Responsibility roadmap as part of the Group’s strategic plan Transform & Accelerate. This roadmap sets out 8 ambitious and concrete 2030 targets supporting the United Nations Sustainable Development Goals (SDGs).

3 April 2019

The Group is taking bold next steps in addressing both environmental topics, to preserve the terroirs its products come from, and social responsibility, in particular by accelerating the fight against alcohol misuse.

Read More: Pernod Ricard article

There’s a new buzz on the vine – Beekist say goodbye to plastic tomato punnets.

1 October 2018

Bee-pollinated tomato brand Beekist® is getting a packaging makeover and it comes in the form of cardboard, replacing their plastic punnets. The move will remove 5.5 million plastic punnets from supermarket shelves or 100 tonnes less plastic that Kiwis take home every year. This is part of T&G’s Growing Green commitment.

Read more: Beekist article